PROJECTS

affordable design

affordable design

Starting with a capstone class in Affordable Design, I have been working with QueenTech - a Ghanaian non-profit focused on equipping women in rural communities. QueenTech builds accessible, small-scale agricultural machines for women who process cassava into gari (a staple Ghanaian and West African dish). This project has grown over many years - a number of employees and a rotating group of students have contributed to the venture.

My personal responsibilities included:

- Acting as Technical Lead to oversee machine architecture changes to improve machine operation, increase reliability, reduce part count and cost

- Traveling to Ghana to build prototypes, meet operators, and repair machines in the field

- Running analysis (hand calcs, and FEA) on machine loading conditions to ensure performance

- Coordinating with overseas suppliers to manufacture custom AC induction motors

stamping optimization

stamping optimization

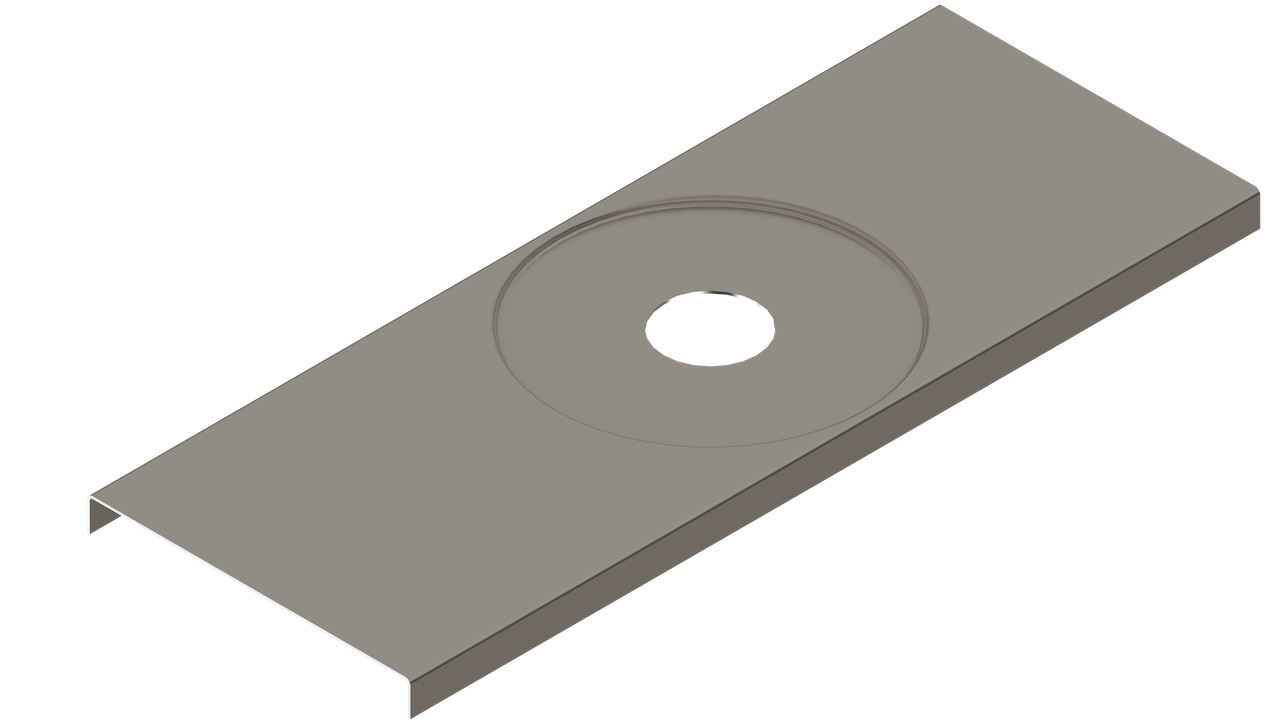

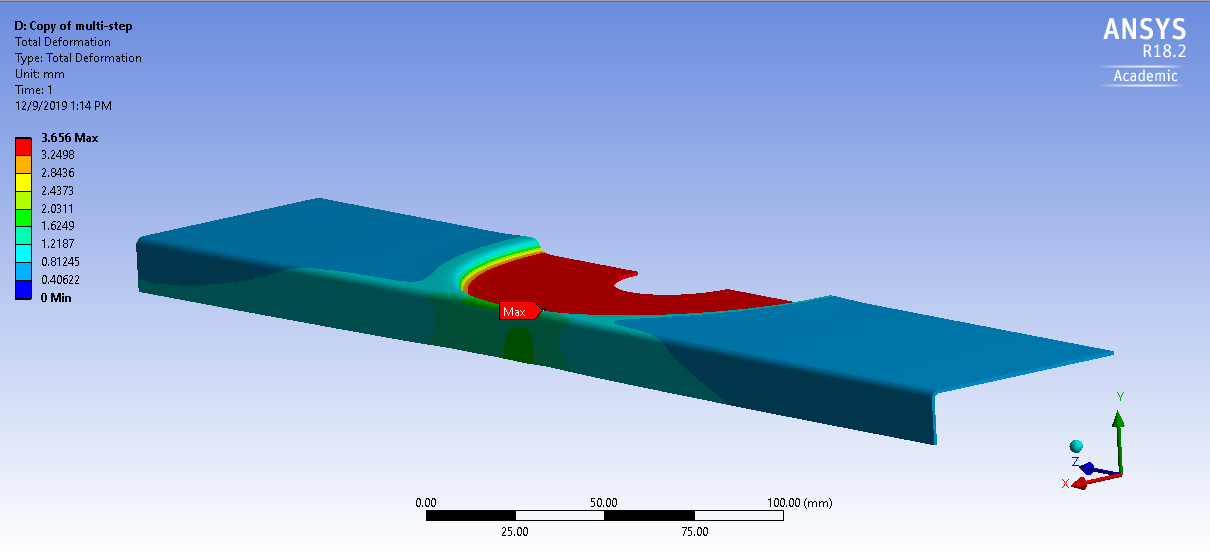

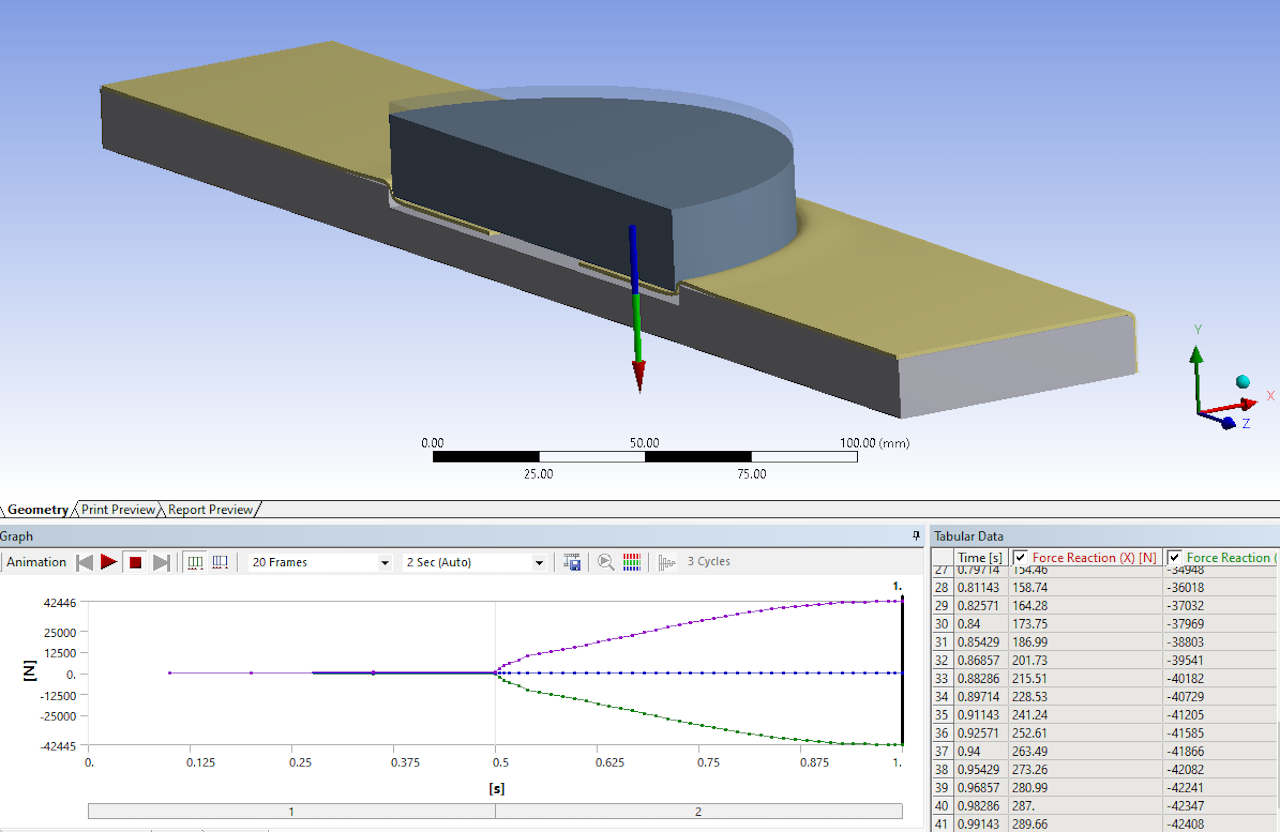

There is one sheet metal component on the Affordable Cassava Grater that requires custom forming. The depth of the drawn feature greatly increases the machine’s performance, but our team had limited access to a large press. After proving that we could adjust tool geometry to greatly decrease the tonnage required, we decided to run an optimization study in Ansys. We aimed to maximize draw depth while staying below a designated tonnage (press capacity). I built a parametric model to vary the sheet metal thickness, punch clearances, and overall punch geometry (fillet radius, circularity). I made sure to use a bilinear material model to capture the plastic deformation. Then, I set up to record the reaction force after prescribing different displacements on the punch. Unfortunately this setup required a fair amount of debugging. I was only able to converge the simulation after simplifying the model, chasing newton-raphson residuals, endlessly refining the mesh, and adjusting the initialization load steps. While I was able to validate our experimental data, further mesh refinements and time stepping adjustments were required to bring the overall computation time down before attempting to run it parametrically.

anodizing

ANODIZING

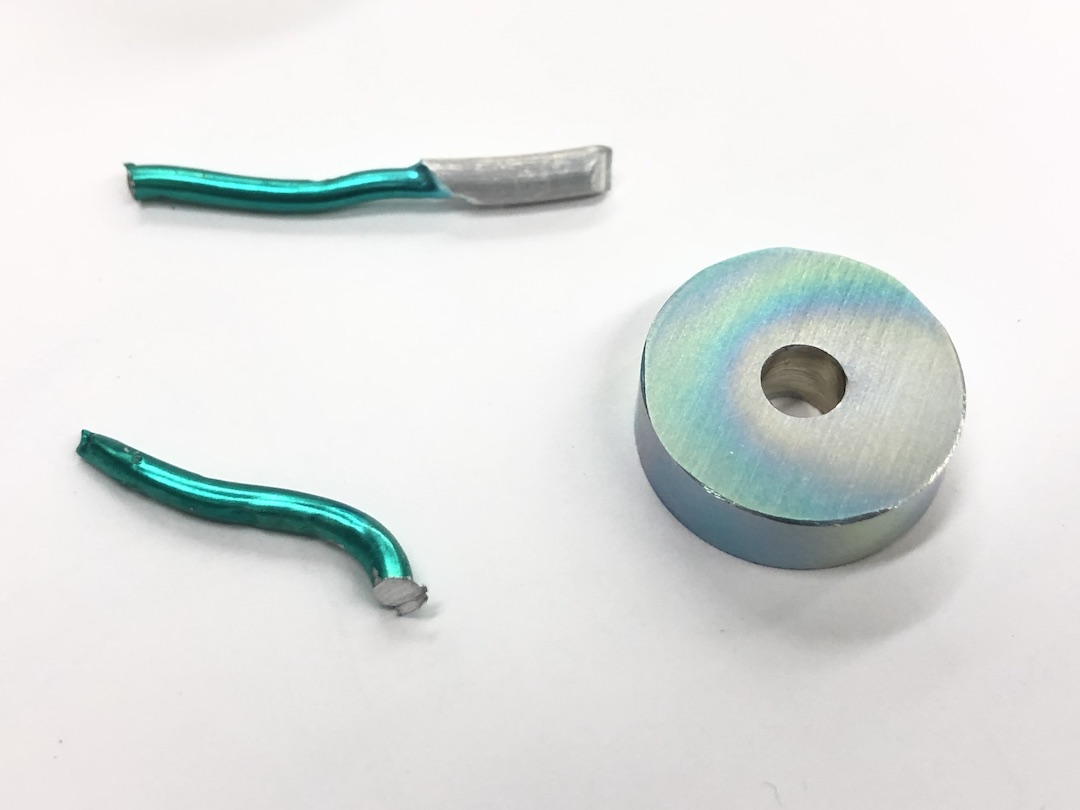

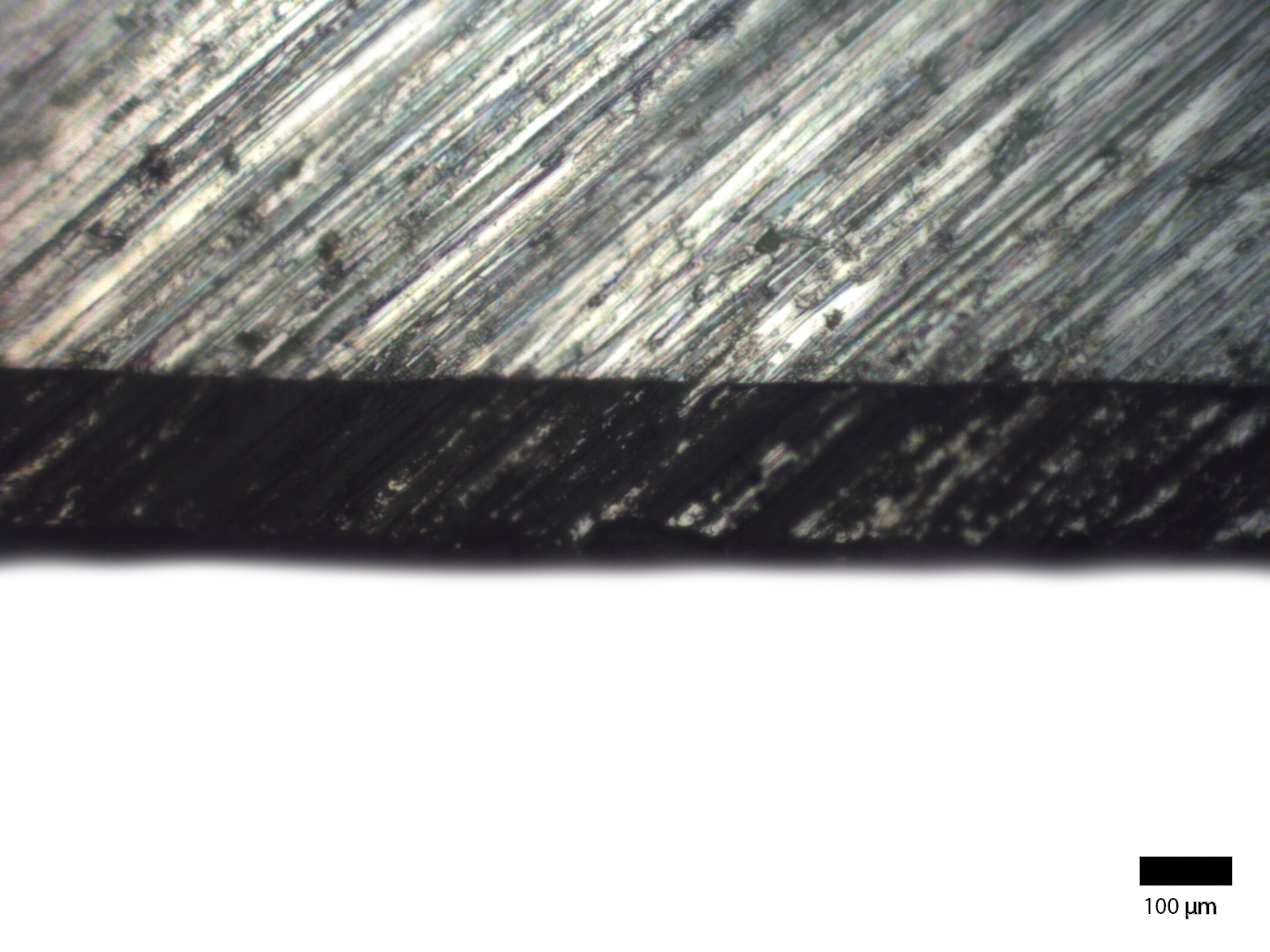

For a Material Science project, my group ran small batch anodizing at Olin. We investigated various processes in literature but found a wide range of recommended operating parameters. We decided to experimentally study the effect of varying current density (among other operating parameters). We then observed the thickness and uniformity of the anodic layer under a Scanning Electron Microscope. We also experimented with adding dyes to the process, and compared our results against an iPhone 6 chassis.

rolling plotter

rolling plotter

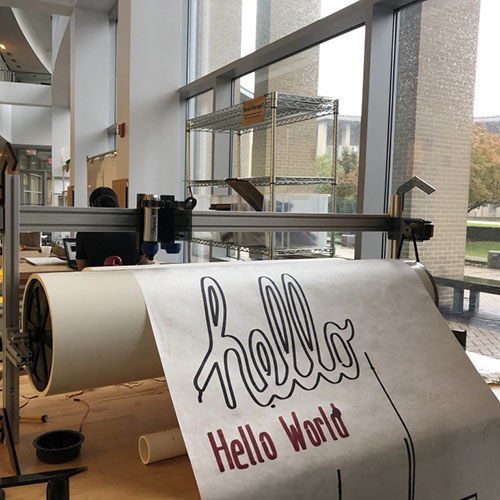

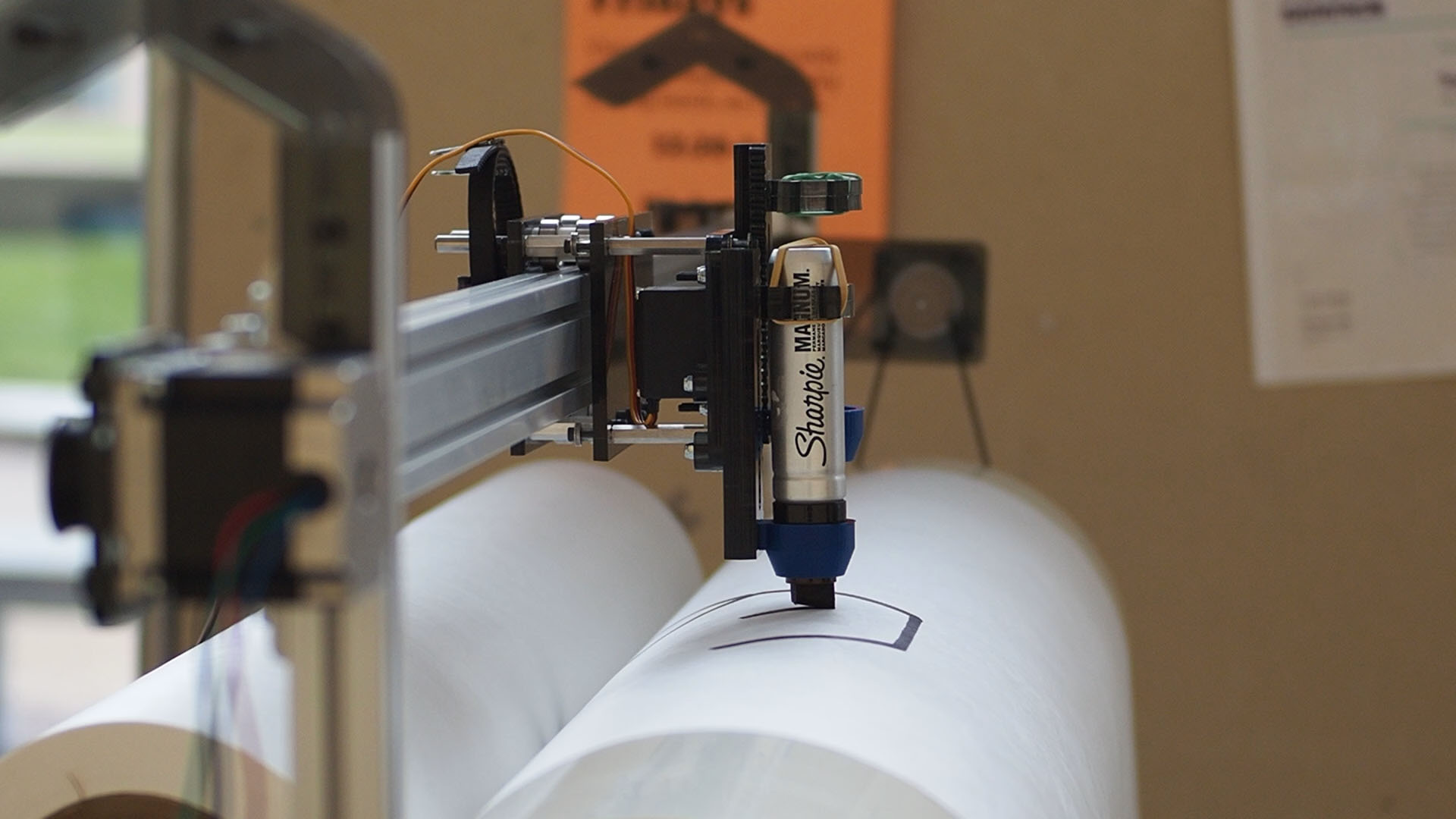

I was tasked with building a large format plotter for the Remaking Education conference hosted by Olin. For the event, we printed ~150 feet of poster on 31" wide tyvek rolls. The design is heavily based off of Thibault Brevet's Grand Central . I designed and built the entire mechanical system in three weeks. Due to the tight timeline, I intended to build the entire system using only laser-cut acrylic and commercial parts from McMaster or Misumi. I am continuously working on upgrades and modifications because Olin has found additional uses for the printer. Full documentation coming soon!

user oriented design

user oriented design

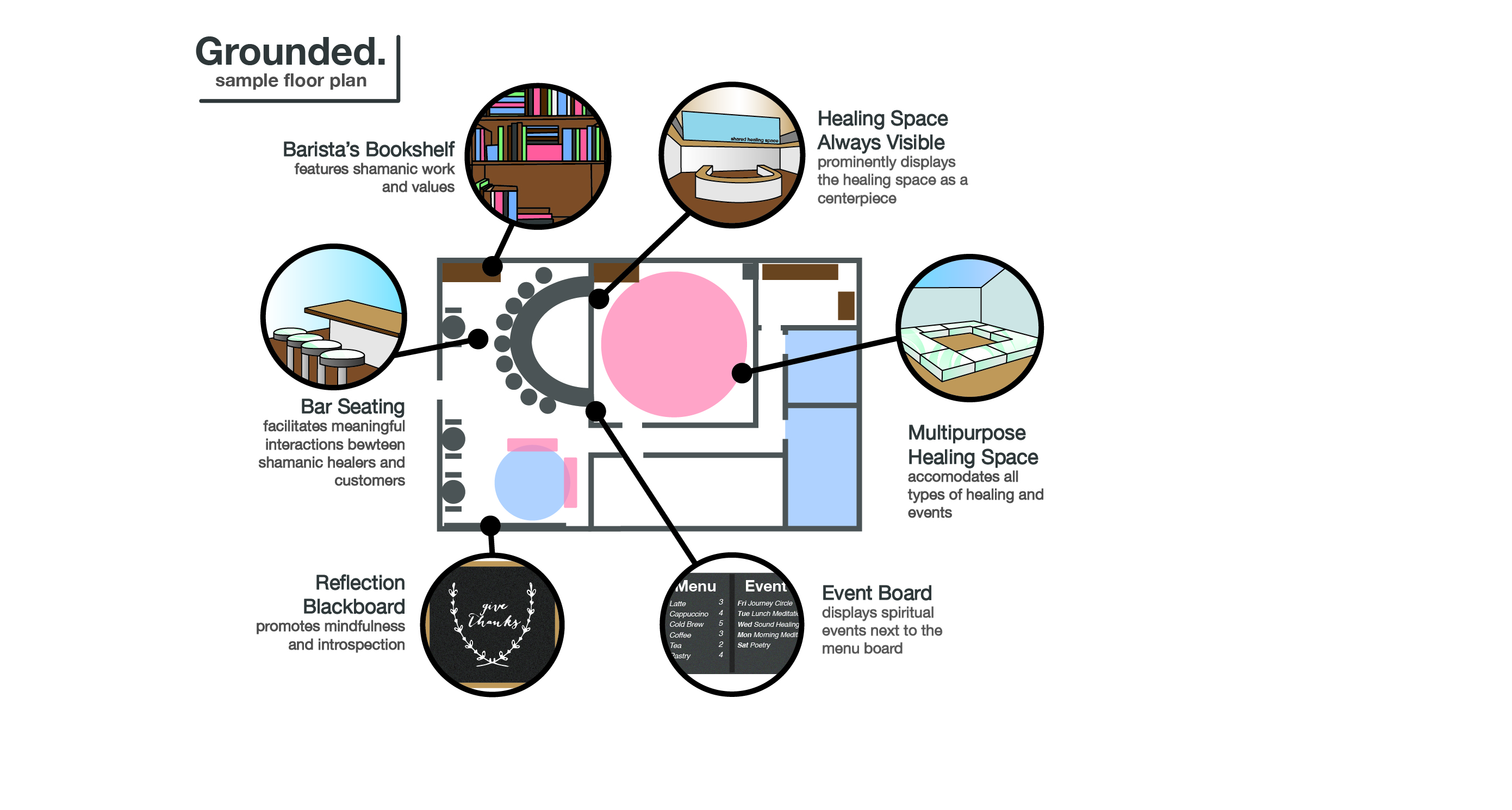

Over the course of my semester in User Oriented Collaborative Design, my team got immersed in the world of urban spiritual healers. We spent countless hours researching their practices, conducting interviews, and even attending shamanic ceremonies. We dug deep into the personalities of shamans we worked with, and came to intimately understand the motivations, passions, and tensions in their lives and practice. My team essentially proposed a coffee shop co-op that lowers the barrier to entry to spiritual healing, and gives shamans a dedicated space in our society.

cnc egg decorator

cnc egg decorator

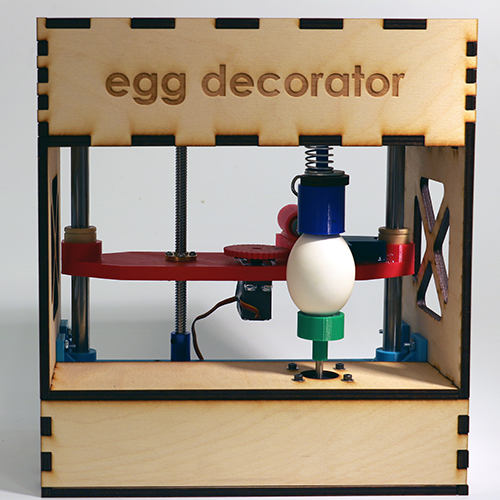

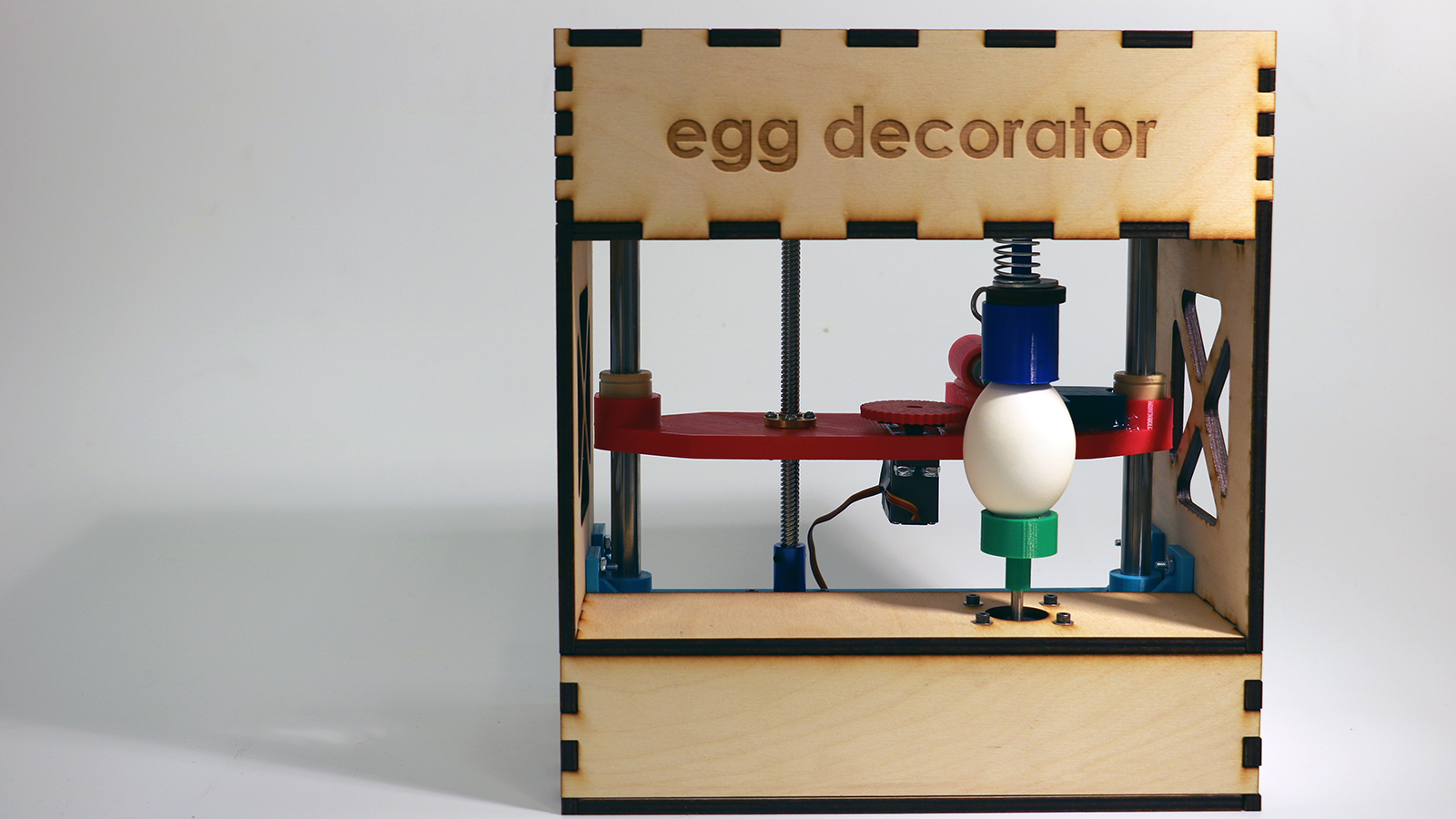

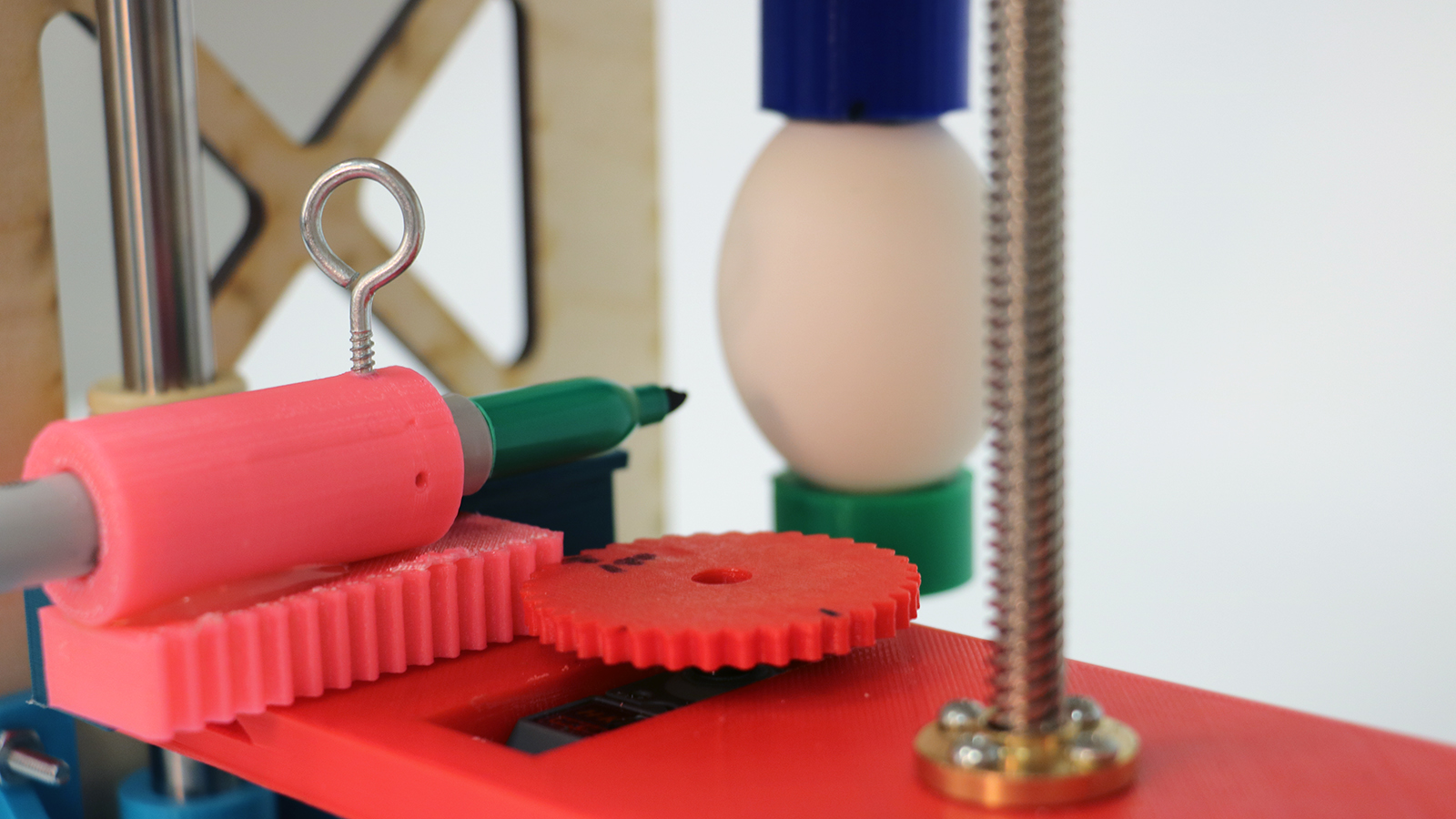

The goal of my Principles of Engineering class was to build a non-trivial electromechanical device within 8 weeks. My team decided to build a 3-axis, cylindrical CNC machine capable of drawing on eggs. As part of the mechanical team, I helped design the machine’s structural elements and subsequently fabricate them using rapid prototyping technologies. The software team made an awesome inkscape plugin that allowed us to draw arbitrary, user-drawn shapes on the eggs. We wrote more about the Egg Decorator and the process behind it on our project website.

volcano robot

volcano robot

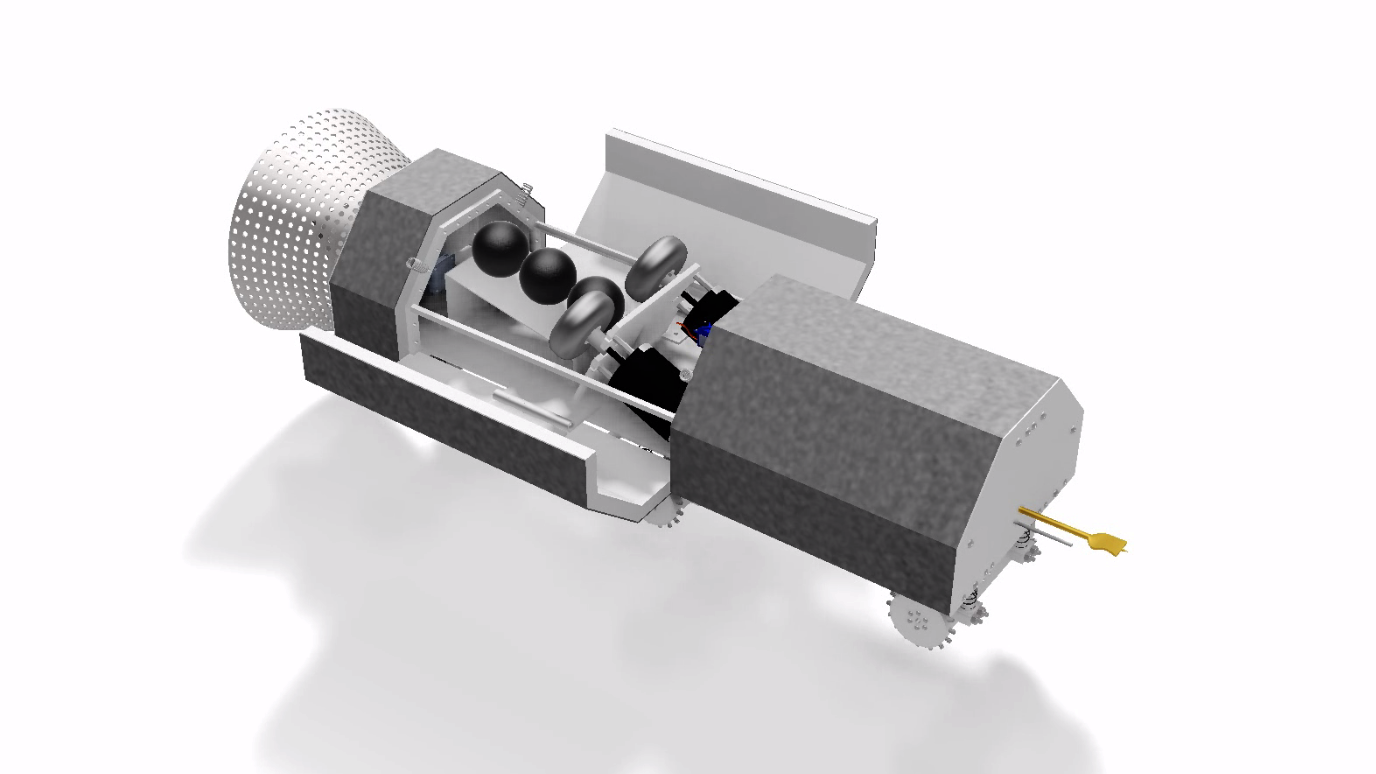

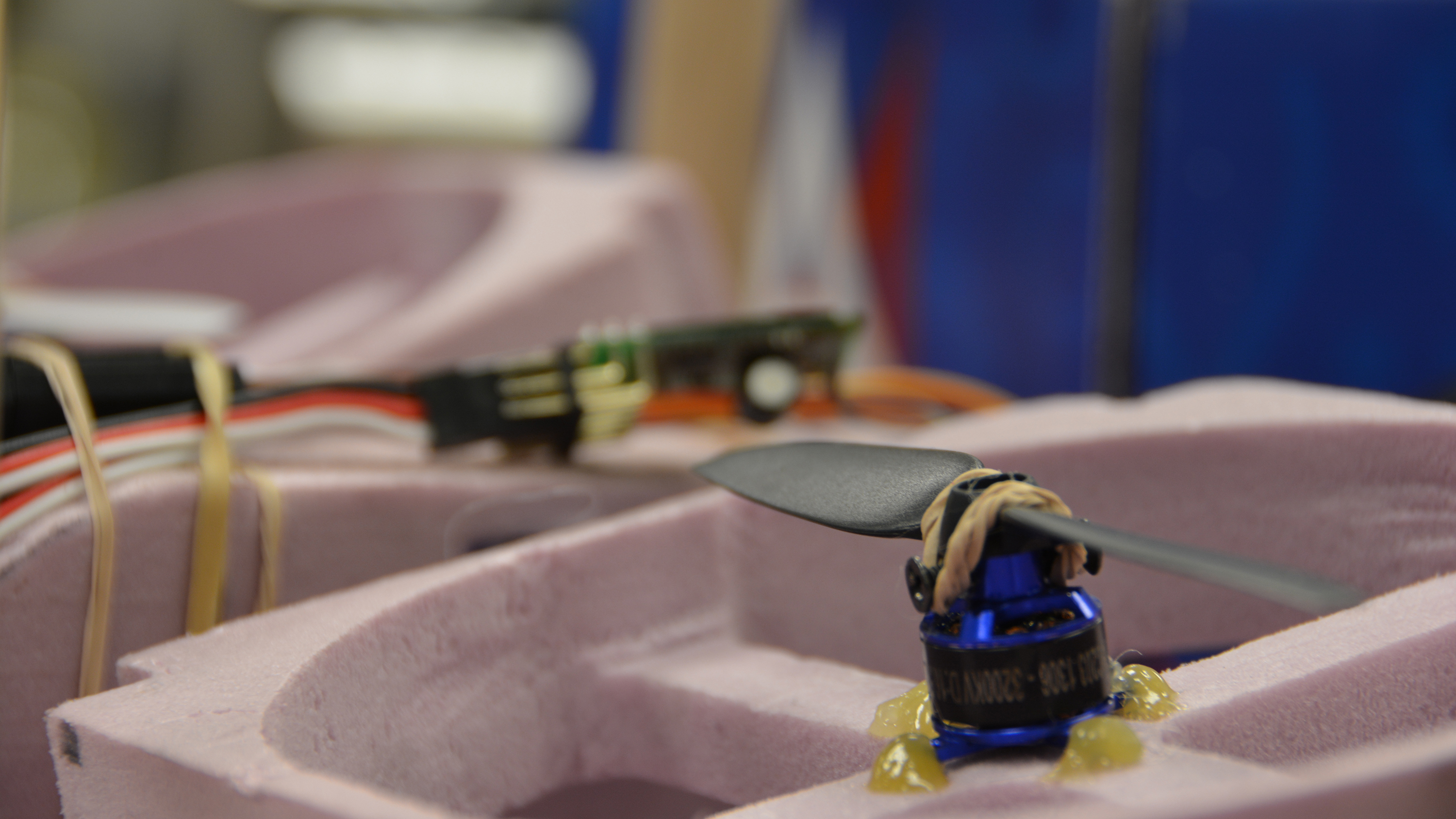

I spent my senior year of highschool creating a volcano exploration robot with a team of eighteen other students. We simulated an industry experience in a classroom environment by establishing a corporate identity - dot, and competing for a contract.

Our team was tasked with creating a machine capable of boring into a volcano, collecting empirical data, and launching a drone to safely relay information. As per industry standard, we meticulously documented our work, and held design reviews with engineers from Boeing, Raytheon, and Northrop Grumman, among others.

documentation

media

push here!

push here

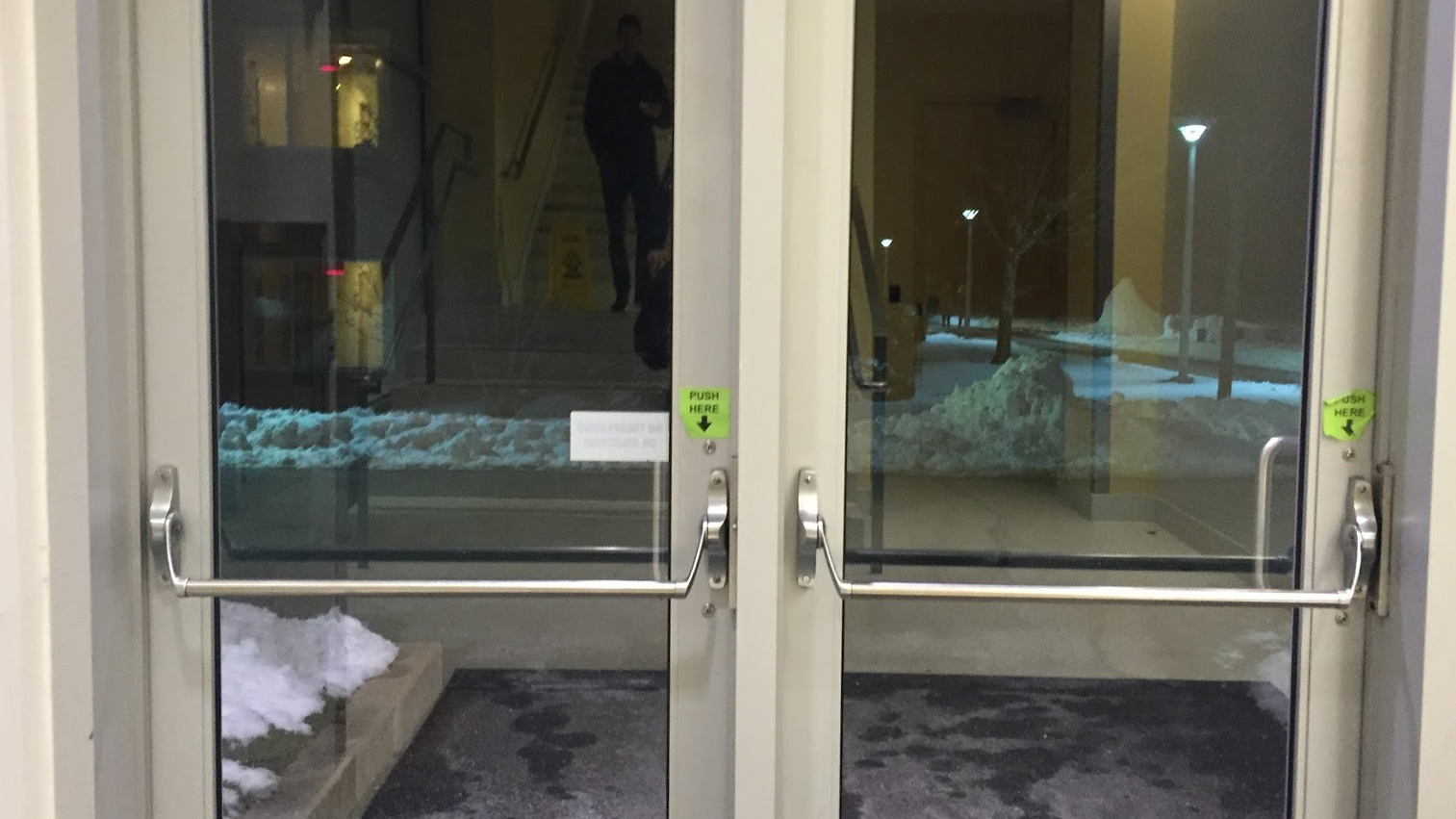

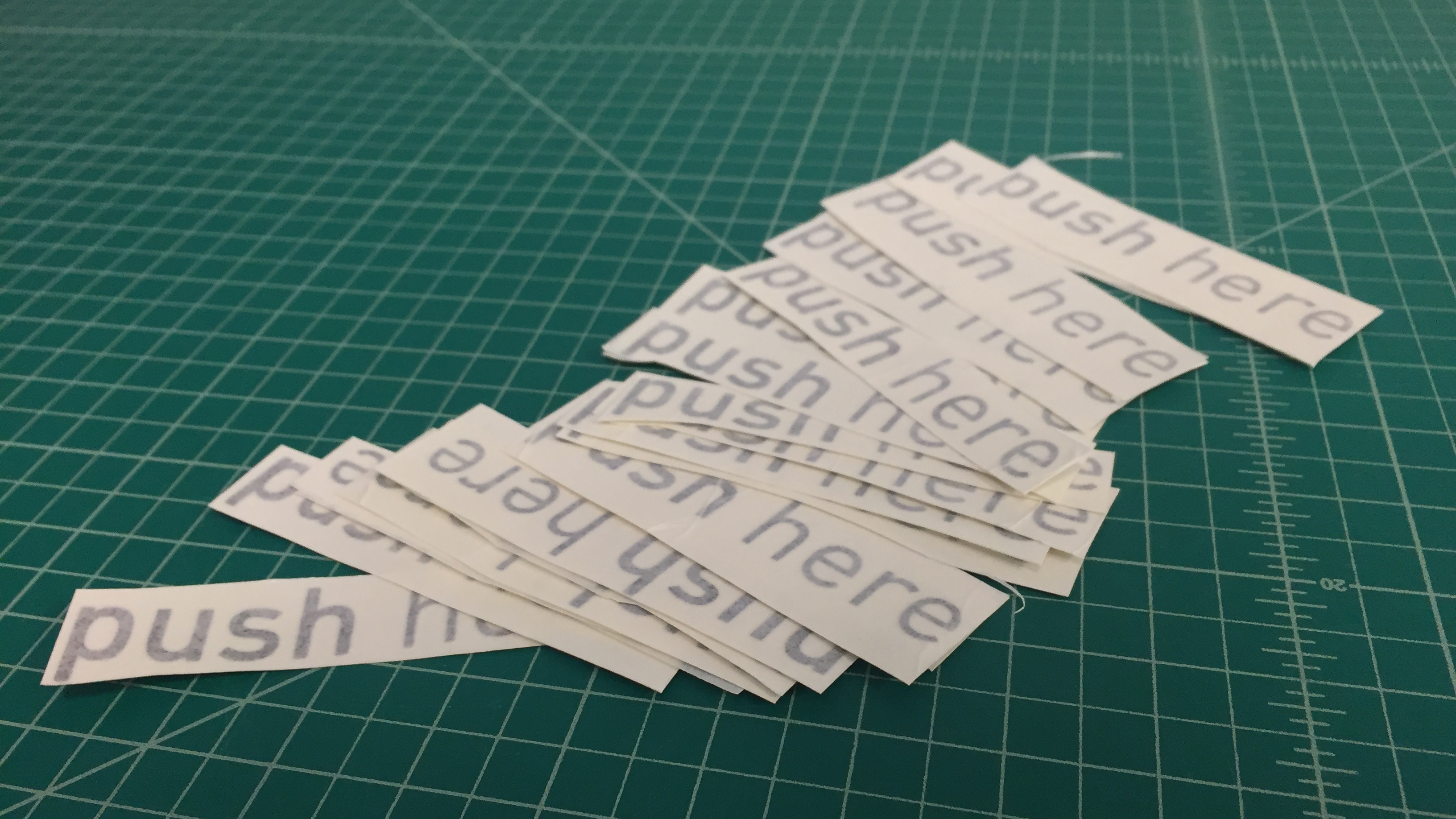

Don’t get me wrong - I love Olin, but for an engineering school there are a few aspects that are pretty poorly engineered. One of the most glaring issues is Olin’s doors. The worst offense is in the dining hall, where there is a pair of doors that open in opposite directions. These unintuitive double doors have always frustrated me. One day I was able to convince a team of students that labeleling the doors would "add value" to the Olin community. We did a test run with post-it notes indicating which side of the door to push. In a follow up survey, over 2/3rds of students admitted the post-its were useful. So, I decided to take it a step further and vinyl cut enough stickers to label all of Olin’s annoying doors.

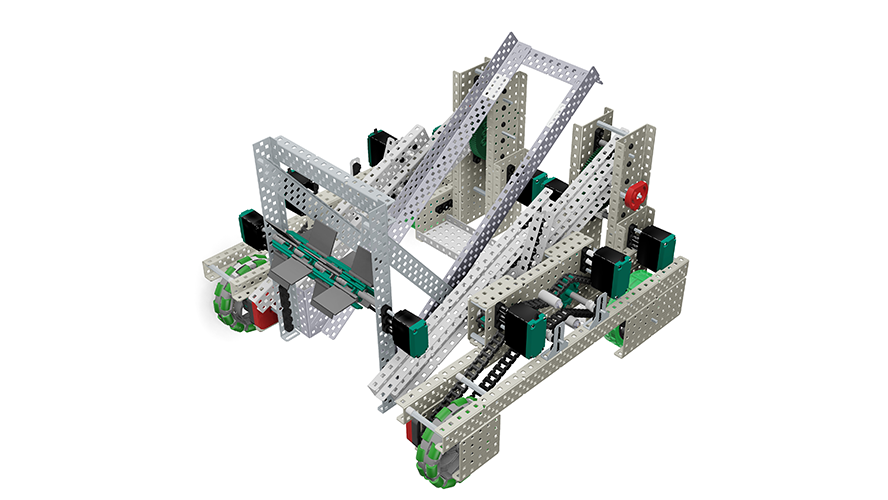

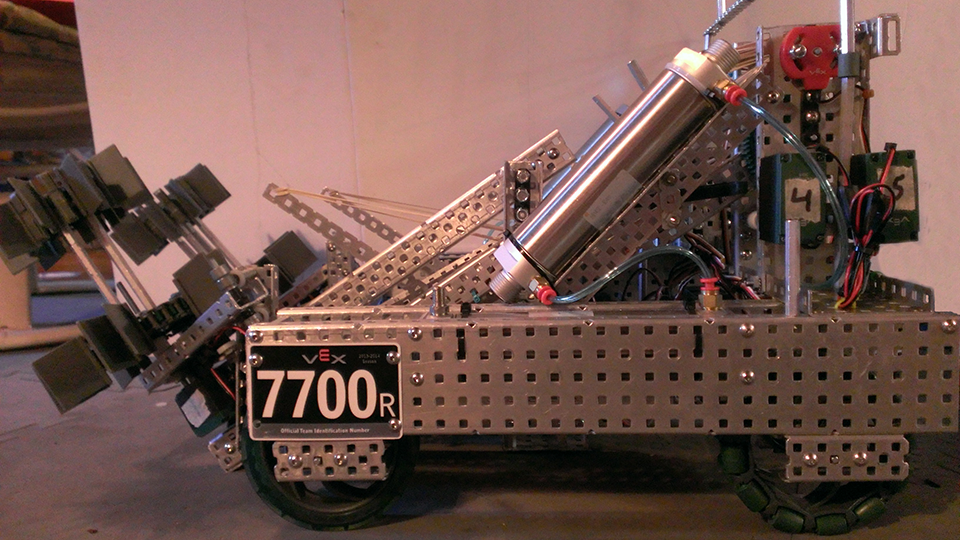

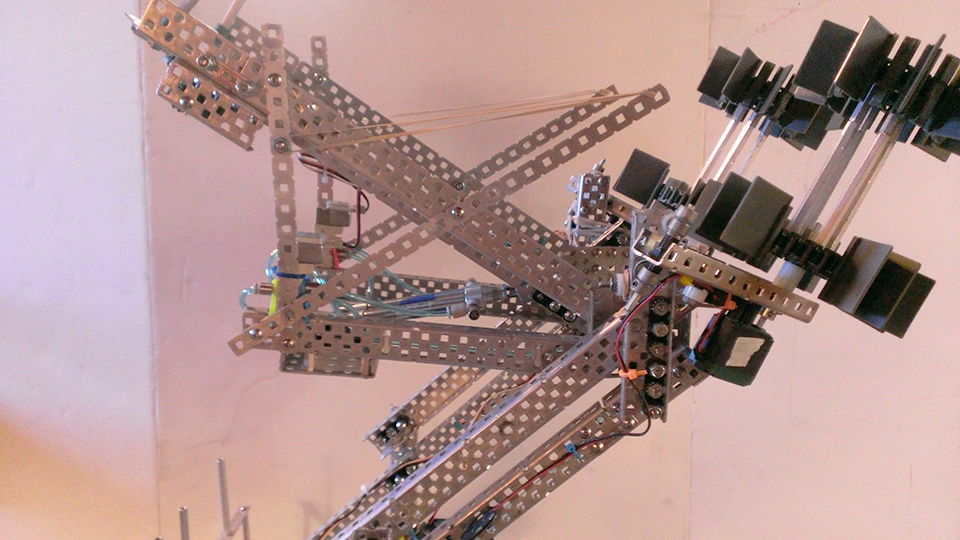

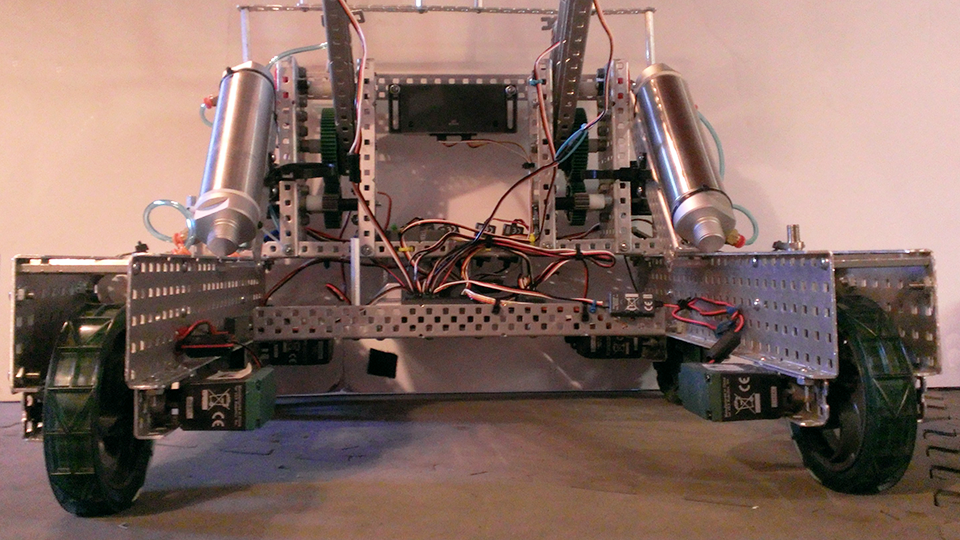

competitive robots

competitive robots

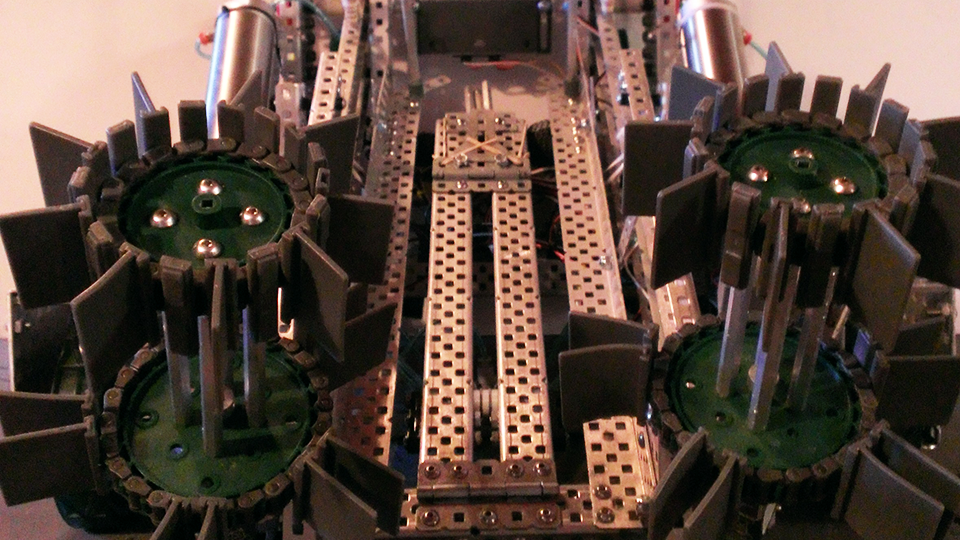

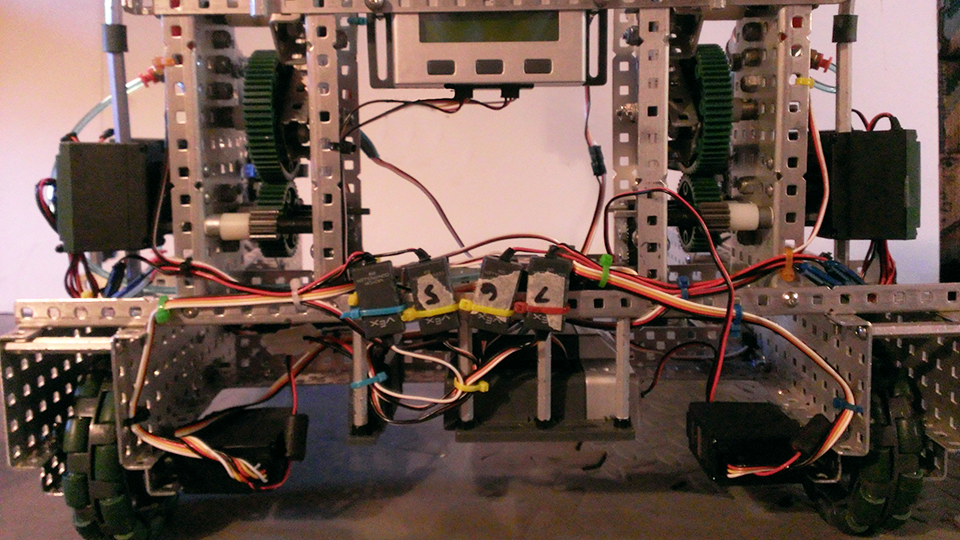

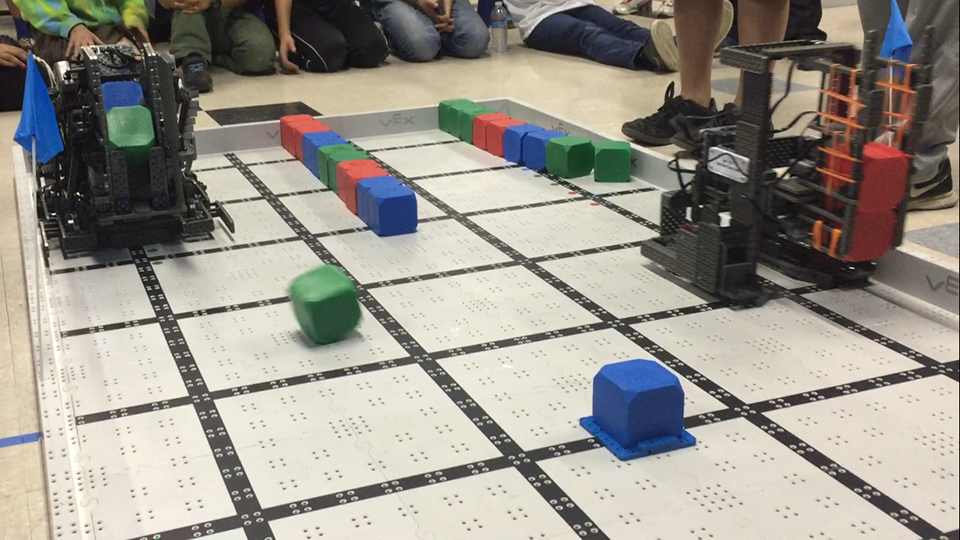

Starting in 7th grade, I participated in an annual robotics competition. VEX robotics was my first experience with hands-on engineering. I often credit VEX as the reason I decided to pursue a career in engineering.

In my last year of competition, my team was fortunate enough to establish a partnership with Rolling Robots, a local robotics workshop. We began mentoring their middle school teams as we transitioned to more challenging robotics projects. It has been amazing to witness the program grow and succeed over the past few. Rolling Robots now has 8 VEX teams and has won tens of awards, including the World's Championship Excellence award.